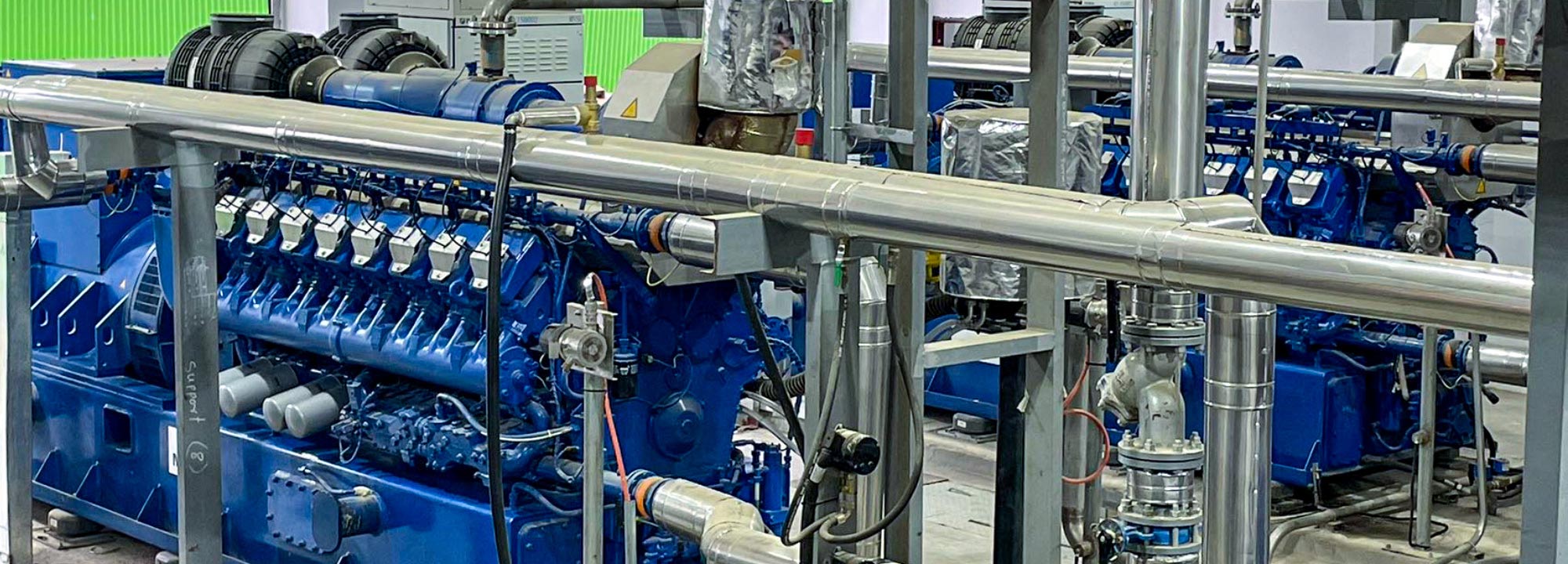

Author:Beijing Pauway Energy Technology Co., LtdTime:March 22 2020Hist:

High efficiency innovation

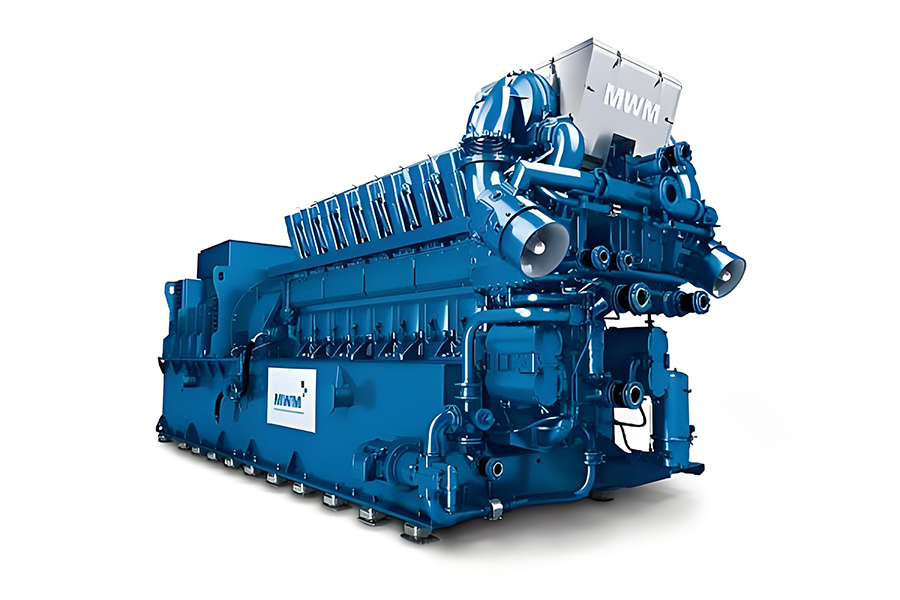

When using natural gas and biogas, the output power of a single machine ranges from 3.300 to 4.500 KWel

TCG 2032 / 3000-4500KW

Product characteristics

Higher returns

Modularization of the cylinder makes maintenance more convenient, reduces the number of disassembled different components, and can minimize maintenance time, saving up to 20% of service costs. At the same time, compared with similar generator sets, it can save up to 30% of lubricating oil consumption, thus enabling you to achieve higher profits.

Longer running time

Compared with similar generator sets, the extension of maintenance intervals allows TCG2032 units to extend their annual operating time by up to 200 hours and their overhaul time can be extended to 80000 hours.

Higher reliability

The use of pre combustion chamber spark plugs for particulate free emission technology, compared to other combustion methods, extends the maintenance cycle of the flue gas waste heat exchanger and reduces maintenance costs. The main components such as pistons, connecting rods, spark plugs, and cylinder heads have been improved to increase output power and achieve higher electrical efficiency.

Best Energy Efficiency

All relevant components have been further improved, and the TEM (fully electronic management) control system monitors all components related to efficiency and output power, especially the up dated and upgraded wastegate valve, which ensures more efficient operation of the unit under constantly changing back pressure conditions. The TEM control system detects the temperature of each cylinder and can respond quickly when there are fluctuations in gas composition. The TEM control system not only controls the engine, but also the entire system, including waste heat utilization.

Full power output

The A140 turbocharger, combined with the upgraded exhaust bypass valve, supports the unit's full power output over a wider range of intake temperatures and altitude conditions.

TCG 2032 50 Hz Technical data

| Engine model |

|

V12 | V16 | B V16 |

|

Cylinder diameter/Stroke |

mm |

260/320 |

260/320 | 260/320 |

| Air displacement | dm3 |

203.9 |

271.8 | 271.8 |

| Speed | min-1 | 1,000 | 1,000 | 1,000 |

| Average piston speed | m/s |

10.7 |

10.7 | 10.7 |

| Length | mm |

7,860 |

9,271 | 9,272 |

| Width | mm | 2,660 | 2,790 | 2,790 |

| Height | mm |

3,390 |

3,390 | 3,390 |

| Net weight of generator set | kg |

43,100 |

51,200 | 51,400 |

| Natural gas application | NOx ≤ 500 mg/Nm3 | |||

| Electric power | kW | 3,333 | 4,300 | 4,500 |

| Mean effective pressure | bar | 20.0 | 19.4 | 20.3 |

| Heat output | kW | 3,238 | 4,164 | 4,259 |

| Electrical efficiency | % | 43.9 | 44.1 | 44.1 |

| Thermal efficiency | % |

42.6 |

42.7 | 43.2 |

| Overall efficiency | % | 86.5 | 86.8 | 87.8 |

| Biogas application |

NOx ≤ 500 mg/Nm3 Lowest heating value (LHV)Hu = 5,0kWh/Nm3 Sewage treatment Biogas [65%CH4 / 35%CO2] Organic Biogas [60%CH4 / 32%CO2 / The rest are N2] Landfill Biogas [50%CH4 / 27%CO2 / The rest are N2] |

|||

| Electric power | kW |

|

3,770 |

|

| Mean effective pressure | bar |

|

17.0 |

|

| Heat output | kW |

|

3,496 |

|

| Electrical efficiency | % |

|

43.0 |

|

| Thermal efficiency | % |

|

39.8 |

|

| Overall efficiency | % |

|

82.8 |

|

TCG 2032 60 Hz Technical data

| Engine model |

|

V12 | V16 | B V16 |

|

Cylinder diameter/Stroke |

mm | 260/320 | 260/320 | 260/320 |

| Air displacement | dm3 | 203.9 | 271.8 | 271.8 |

| Speed | min-1 | 900 | 900 | 900 |

| Average piston speed | m/s | 9.6 | 9.6 | 9.6 |

| Length | mm | 8,000 | 9,420 | 9,420 |

| Width | mm | 2,790 | 2,790 | 2,790 |

| Height | mm | 3,390 | 3,390 | 3,390 |

| Net weight of generator set | kg | 40,650 | 52,400 | 52,400 |

| Natural gas application | NOx ≤ 500 mg/Nm3 | |||

| Electric power | kW | 3,000 | 4,000 | 4,050 |

| Mean effective pressure | bar | 20.1 | 20.2 | 20.4 |

| Heat output | kW | 2,877 | 3,866 | 3,891 |

| Electrical efficiency | % | 43.9 | 43.9 | 44.3 |

| Thermal efficiency | % | 42.1 | 42.4 | 42.6 |

| Overall efficiency | % | 86.0 | 86.2 | 86.9 |

| Biogas application |

NOx ≤ 500 mg/Nm3 Lowest heating value (LHV)Hu = 5,0kWh/Nm3 Sewage treatment Biogas [65%CH4 / 35%CO2] Organic Biogas [60%CH4 / 32%CO2 / The rest are N2] Landfill Biogas [50%CH4 / 27%CO2 / The rest are N2] |

|||

| Electric power | kW |

|

3,510 |

|

| Mean effective pressure | bar |

|

17.0 |

|

| Heat output | kW |

|

3,125 |

|

| Electrical efficiency | % |

|

43.3 |

|

| Thermal efficiency | % |

|

38.5 |

|

| Overall efficiency | % |

|

81.8 |

|